VeriVin: using spectroscopy for non-destructive testing of wine

Website: https://www.verivin.com/

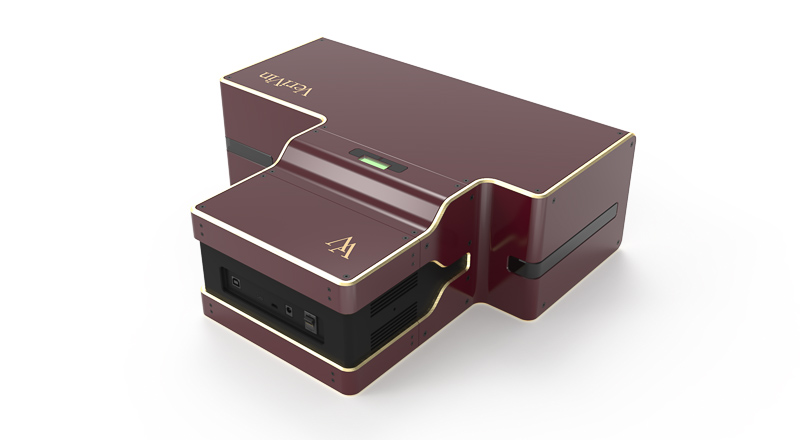

Dr Cecilia Muldoon is a wine-loving physicist whose invention, a device for the non-invasive identification of the contents of a wine bottle, has the potential to shake up the wine industry. In particular, it could represent a big step forwards in the process of authenticating wine for auction. I travelled to the Oxfordshire offices of her small start-up, VeriVin, to find out more.

When I arrive, the small team is busy working on a portable prototype of their machine, because the following week they’ll be taking it to Argentina to give it a thorough real-world environment try out. Everyone seems excited and daunted by the prospect in equal measure. As we chat, I get an understanding of just how many difficulties they’ve had to face to get this far. It’s technically hard to examine the chemistry of an unopened bottle of wine, but it looks like they might be able to pull it off. Dr Muldoon explains to me how it works, and what the challenges are working with intact bottles of wine in a non-invasive way.

First, though, in order to understand how this machine works, some context is needed. Let’s begin with the concept of ‘light’. Our visual system is able to detect light in what is known as the visible part of the electromagnetic spectrum, which is a set of frequencies ranging from around 400 nm (this looks blue) to around 700 nm (this looks red). The full spectrum includes frequencies that we can’t see (it ranges from radio frequencies that are harmless to the sort of radiation that got released in the Chernobyl disaster that have enough energy to be extremely harmful). The light from the sun has all these visible frequencies in it (as well as others, such as ultraviolet and infrared), and so is described as polychromatic light. These visible frequencies can be separated – for example by a prism – and then you see them individually. A rainbow is a good example of this sort of separation.

When polychromatic light shines on an object, some frequencies are absorbed and some are reflected back or transmitted. So a post box is red because it absorbs the shorter wavelengths and reflects the red spectrum. A tyre is black because it absorbs all the frequencies, reflecting none back.

Spectroscopy is a technique in the physical sciences that takes advantage of the way that electromagnetic waves hit solid objects and then either pass through, are absorbed, or bounce back. The idea is that you shine a particular frequency of the electromagnetic spectrum (it can be light, or another frequency, such as X rays) at an object and then examine how the light is absorbed, reflected or transmitted by the object. This then tells you something about the object. A famous example of this is how the structure of DNA was worked out by Rosalind Franklin, Francis Crick and James Watson back in the 1950s, using X ray crystallography. They exposed DNA to X rays and then from the resulting pattern of blobs on a photographic film they were able to work out that it was an alpha helix structure. One of the great mysteries of life was solved.

Muldoon and her colleagues are using a special sort of spectroscopy that makes use of what is called Raman scattering. This is a reasonably complicated idea, but I’ll try to explain it in a way that makes sense to a non-physicist (like me). What you do is take a high intensity laser at one particular frequency and shine it at a substance you are interested in investigating. A very small proportion of the photons – around one in 10 million – will interact with the molecular vibrations in the structure of the molecules present and change their frequency, and then bounce back. So you need to filter the light that is reflected, leaving just this tiny fraction that represents the Raman part, and which tells you something interesting. This light is then split up using a diffraction grating, and the result is a chart with peaks at certain frequencies. Effectively you have a fingerprint of the sample. This technique was invented by CV Raman who received the Nobel Prize for it in 1930.

Muldoon’s inspired idea was to take Raman spectroscopy and apply it to wine. [It came to her as she was finishing off her PhD on trapping single atoms in extreme vacuum with lasers, with a view to using this technique in quantum computing. But that is another story.] Of course, there are lots of analytical techniques for looking at the chemical composition of wine. The problem is, they are destructive, and it would be incredibly useful to be able to examine unopened bottles of wine, particularly with fine wine that is worth a lot of money. But there are several challenges that she’s had to face in developing this new technology. The first is that wine is a liquid.

‘If light interacts with a solid, you will have a well-defined fingerprint,’ says Muldoon. ‘Every molecule gives a different set of momentum kicks to the light, and the pattern of momentum kicks you get when you have a solid are very precise. But when you have a liquid, because everything is moving around and the molecules are bumping into each other, it means that the time for the light to interact with each molecule is shortened.’ The result is that with a liquid the resolution of the pattern – how precise it is – is reduced.

The second challenge is the nature of wine itself. ‘If I gave you a bag of white powder at the airport and said, “is this flour or cocaine?”, you can take a Raman spectrum to determine what it is,’ explains Muldoon. ‘Once acquired, the spectrum would be compared against a library containing the spectra of many different compounds, in which you would see that cocaine looks like this and flour looks like that.’ The problem is fairly well defined, as te powder is (presumably) composed of one predominant chemical compound. ‘The problem with wine is that you have got 85% water, 12-14% ethanol, and then more than 1000 molecules of interest which make up the remaining 1-2%,’ she says.

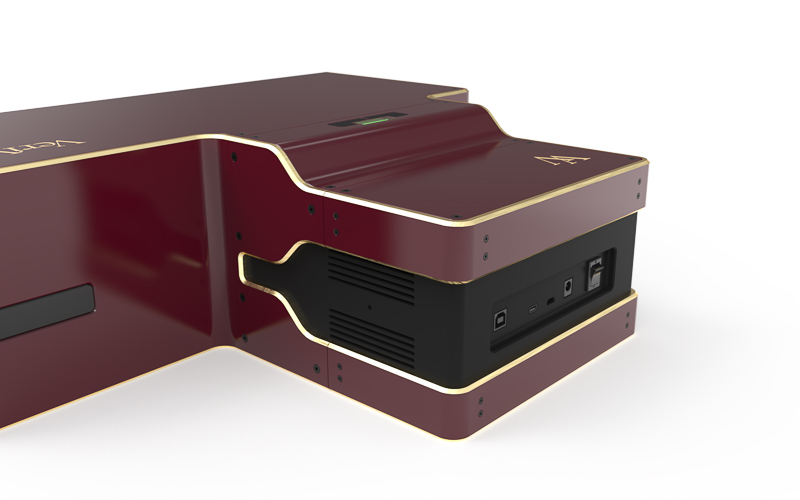

And this 1-2% – what you want to look at – is in the form of a liquid inside a sealed container. And the sealed container represents the third challenge. ‘It turns out that glass is the worst wall you can encounter as a barrier,’ says Muldoon. ‘Plastic is easier: we can look through plastic, because it has a clear signature.’ The problem the container presents is twofold. ‘One, it is going to attenuate the light going in. Worse than that, once the (already attenuated) incident light has interacted with the contents – and recall that only one in 10 million photons are Raman scattered, which means an already super-weak signal – it must once again traverse the glass to come back out, which means it too will get attenuated.’ So the glass is acting like a dark pair of sunglasses, dimming the light going in and the light coming out. ‘Also, the scattered light is going out in every direction, and the fraction of it you can capture is limited by the size and geometry of certain optical elements, which means you get even less light.’

On top of this, the glass itself has a signal. ‘The glass does exactly the same as the wine: it will generate both Rayleigh scattering and Raman scattering.’ The signal that comes out is therefore the signal of the wine plus the glass. Glass is worse than the plastic because it varies hugely from bottle to bottle in composition. ‘There are striations, changes in thickness, and recycled glass is even worse,’ she says. ‘We started out doing a big test in Italy where Edoardo [Ceci Ginistrelli, a member of the team] took the absorption curve of 70 different bottles. We wanted to garner where the best place to work in terms of the frequency [of the laser] was.’ In the absorption spectrum of the glass there are dips and peaks. ‘You don’t want to work where it absorbs a lot, but also you don’t want to work where the absorption is changing a lot. You want a place where it is quite flat.’ There are other considerations to do with the wine (or other contained substance) which also influence the choice of laser frequency, but the glass is an important constraint.

Interpreting the signal is the next challenge. ‘There are 1000 different molecules in that 1-2%, and each has a spectrum of its own,’ explains Muldoon. ‘They are small wiggles on the total combined signal coming from the wine, which looks predominantly like ethanol. At the end of the day, because the number of photons coming from the ethanol versus any of the other molecules is so much higher, the naked eye basically only sees the spectrum of ethanol. However, software can see the small wiggles. So it is essentially a signal processing problem. It’s a bit like finding a needle in a haystack.’ They use a statistical analysis technique called chemometrics to understand the wiggles. ‘It is a bit like machine learning,’ she says. ‘The algorithm we have developed breaks the main signal into mathematical components and can then class things according to those components. Those components will change according to what was present in the wine.’

‘When we started out, we wanted to do a proper molecular decomposition, to say there are N moles of this molecule and N moles of that molecule,’ she says. ‘We very quickly realised that this is nigh-on impossible. We just don’t get enough photons.’ Initially, the hope was that VeriVin might be able to spot cork-tainted bottles. But TCA is present in such low quantities that this won’t work.

So far, this is just the hardware side: minimizing the impact of the glass, and choosing the best laser frequency to work at for wine. ‘Then you come to the software side. This is even more challenging. The way the algorithm works, it needs as many data points as possible to be accurate. The more data points you have the more accurate it is. We have tried to test as many things as we can in controlled environments. We have taken different wines and left them to purposely oxidise for a number of hours or a day, and tested again. We’ve put them in the oven. We’ve tried to do different vintage testing, and we have done a lot of experiments where we have swapped bottles (the contents of one bottle swapped for another), to make sure we are dealing with the glass problem correctly.’

Given a training set, VeriVin is very good at classifying wine, and can see different recent vintages, or it can distinguish different grape varieties, or it can identify oxidised bottles. The training set is key. Ideally, they will have enough data points so they can take a bottle labelled Lafite 1985, and say whether this has the fingerprint of the real thing. Now that the machine is working, she is turning her thoughts to real world applications for VeriVin. ‘From starting out with a business case and a very difficult physics problem to solve, we now have a very difficult physics problem that we have addressed, and we need to readdress our business case.’

VeriVin is designed for looking at wine inside glass bottles. But this machine can also examine honey and olive oil (she’s tried this and it works), as well as blood bags and pharmaceuticals. ‘We are starting out with wines and spirits and then moving on to other industries,’ she says. Other Raman spectrometres are in commercial use already. ‘At Heathrow, there are these big red boxes at some of the security gates,’ Muldoon says. ‘They are Raman spectrometres that look for explosives inside of plastic or glass containers. Why is that problem easier than wine? Explosives by definition have to be present in high concentrations to be explosive, so they are easy to detect, and plastic is easier to deal with than glass.’

The main wine targets of VeriVin are authentication (anti-counterfeiting) and quality control. They are currently talking to big drinks companies, auction houses, merchants and some collectors and producers, as well as other companies working in the wine and spirits and wider beverage industry. ‘It has taken a while for us to approach anyone,’ says Muldoon. ‘When I started on this, we had a great business case but an unsolved physics problem. So from investors to people I spoke to, everyone would say, where’s the prototype? Or, it can’t be done. Now that we have emerged from this R&D period, I’m finally happy that we have a machine we can go out and make a splash with. But I want to be prudent and be very transparent as to what it can and cannot do. There are a lot of black boxes and magic machines out there. Science is not always as honest as people believe. This is not a magic box.’

Muldoon is focused now on making some of the development costs back. ‘The kick back we have at the moment is that we need to start charging money for this.’ To this end, she has developed a Pioneer Program, with a provisional pricing scheme that favours the early adopters. Initially, their challenge was hardware. Then, when they saw the device worked, it became one of software. The number crunching wasn’t automatic, but had to be done by someone in the lab. This has now been solved, and this makes the device a lot more scaleable. Once you have a device in your hands, it is controlled by an app (your phone and the device pair via bluetooth), and the information is sent back to the VeriVin servers for some number crunching, and you get your results.

They are getting lots of enquiries from people in the wine trade. ‘You have no idea how many people contact us all the time. Can you solve my cork taint problems? Can you scan my whole production? Someone contacted us a few days ago saying I want to scan a million bottles for a client.’ The scan itself takes between 5 and 30 seconds. What takes the time is loading the bottle, and then doing the analysis.

I ask: at the moment, if I came to you with some old wine, what could you say to me about that old wine? ‘We could scan it and test it against other bottles,’ says Muldoon. ‘We’d need to go out and get more bottles of the same wine. This is the database problem.’ Would going to Bordeaux and going through the cellars of various Châteaux be a useful exercise? ‘Yes, and this is partly where we are frustrated. We need data very badly. Muldoon has strong connections with Oxford University, and so one thought is to test all the wines in the cellars of the colleges. Professor Steve Davies who is chairman of VeriVin has a large collection and they are going through and testing many of the bottles in his cellar. In a recent test they found that they could distinguish between a sound bottle of an old wine, and one that was oxidised. ‘Essentially, we tested 70 bottles of what were meant to be exactly the same wine, and the algorithm lumped exactly half the bottles in one place and half the bottles in another,’ Says Muldoon. ‘It wasn’t like a drift or gradual trend (which could have been attributed or instance to some issue with the device – temperature fluctuations or other electrical noise) – it was literally two distinct classifications. And we could find no pattern or symmetry in the way they were stored that could possibly indicate a difference, and no other possible reason why it could be. We did the test three times just to be sure. The strangest part: Steve claims that all the bottles came out of exactly the same cases, bought from the same trustworthy merchant, bought directly from the Domaine, and that they haven’t moved from that storage condition in the cellar since.’ They opened some of the bottles. ‘All of us concluded that one was totally dead and oxidised and past it, and the other one was great. We opened another two bottles, one from each batch, and the same again.’ She sent some of the bottles to Jancis Robinson, who came to the same conclusion. VerVin was able to identify the out of condition bottles. ‘This is a model we now think we could use more widely now,’ says Mudoon: ‘mass testing with spectroscopy and then you only have to open one of each different batch to test for the particular problem.’

So why is Muldoon about to head to Argentina? VeriVin have been working with Mike Barrow, who owns Costaflores Organic Winery. This winery describes itself as the world’s first open-source winery, and is into blockchain and cryptocurrency. ‘He has been willing to defer bottling this year, and bottle in different glass with different closures,’ she says. ‘We are doing two weeks out there and all sorts of controlled experiments.’ The same batch of wine was bottled in different types of glass bottles with different closures and stored under different types of illumination (e.g. UV, cold light, warm light). The evolution of the wine will be followed over time using both through-barrier and invasive analysis. During this trip, VeriVin also established a solid network in Mendoza and engaged with local research institutes and government. Government officials were especially keen to work with VeriVin on vetting the authenticity of their exports to regions where counterfeiting is an issue for them.

Will VeriVin end up being an important tool in authenticating wine? There’s certainly a need for it. Now that Muldoon has a device that works, the big challenge is twofold. First, they need to acquire a reference database of scans of many thousands of collectable wines. They need to then test the same wine and see how much the scan varies with ageing in different conditions, and with different quality corks (as we so often say in the wine trade, there are no great old wines, only great bottles). Once a wine is of a certain age, even the bottles in the same case will all be slightly different, and the database will need to take this into account. The second challenge is to make this device pay. Such is the need for reliable authentication, that if these significant challenges are met, then this technology will revolutionise the secondary wine market.